- By Admin

- Dehydrated Onion, Garlic powder

Why Indian Dehydrated Onion & Garlic Products Are in High Global Demand

Introduction: Why the World Is Turning to Indian Dehydrated Onion & Garlic

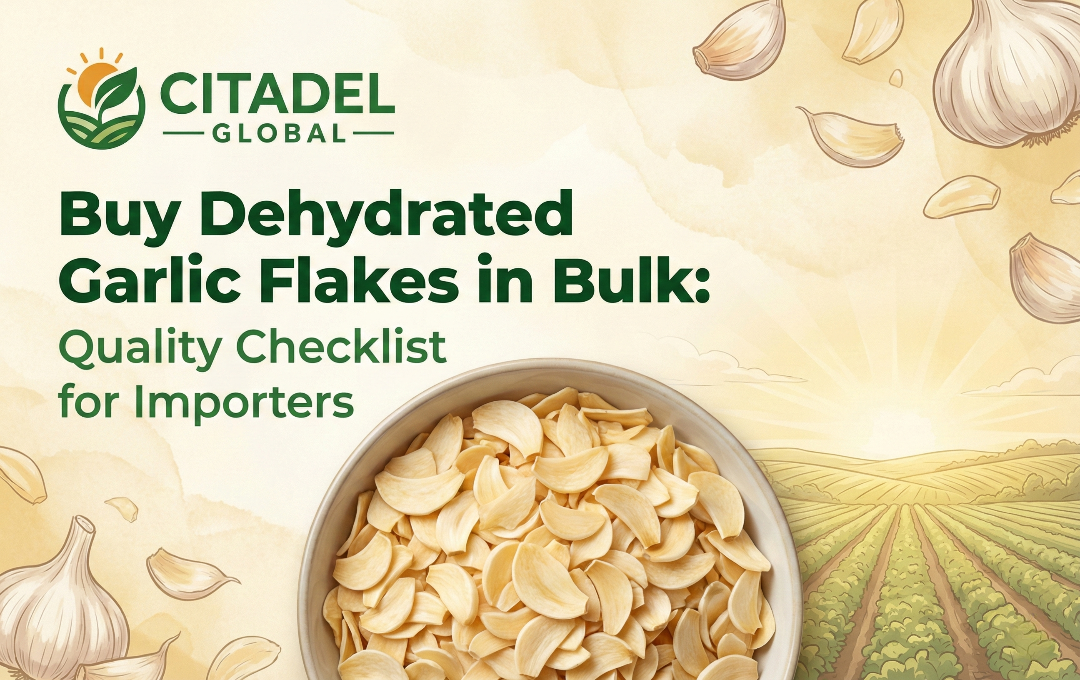

Fresh onions spoil. Garlic prices swing. Global food businesses don’t have the luxury of inconsistency. That’s exactly why dehydrated ingredients have moved from being a backup option to a strategic necessity—and why Indian Dehydrated Onion and Indian Dehydrated Garlic Powder are now in high demand worldwide.

Across food processing, HoReCa, FMCG, and institutional kitchens, buyers are rethinking sourcing models. They want ingredients that are shelf-stable, cost-efficient, scalable, and compliant with international food safety norms. India has quietly emerged as a dependable answer—combining agricultural scale, processing expertise, and export readiness. This guide unpacks why India leads the global dehydrated onion and garlic market, what buyers should look for, and how the ecosystem supports long-term sourcing.

Understanding Dehydrated Onion & Garlic Products

What Are Dehydrated Onion Products?

Dehydrated onion products come in multiple formats—flakes, granules, powder, minced, chopped, and kibbled. These forms are widely used in soups, sauces, seasoning blends, snacks, frozen foods, and ready meals where flavor consistency matters more than fresh appearance.

Unlike fresh onions, dehydrated onion flakes and powders offer predictable pungency, uniform particle size, and long shelf life—critical for industrial food production.

What Is Indian Dehydrated Garlic Powder?

Indian Dehydrated Garlic Powder is produced by carefully drying fresh garlic cloves under controlled conditions, then milling them into standardized mesh sizes. Food manufacturers prefer powdered garlic because it blends easily, delivers consistent flavor, and eliminates peeling, spoilage, and labor costs.

Why Dehydration Matters in Modern Food Supply Chains

Dehydration dramatically improves shelf stability, reduces wastage, lowers transportation costs, and supports clean-label formulations. For global buyers, it also simplifies inventory planning and reduces dependence on volatile fresh produce markets. This is why dehydrated garlic granules and dried onion formats are becoming non-negotiable inputs.

India’s Agricultural Advantage: The Foundation of Global Demand

Ideal Climatic and Soil Conditions

India’s diverse agro-climatic zones support large-scale onion and garlic cultivation. High sulfur content in Indian soil contributes to stronger aroma, higher pungency, and better solid content—traits highly valued in dehydration.

Scale of Production and Global Ranking

India consistently ranks among the world’s top onion and garlic producers. Unlike many onion producing countries, India offers year-round raw material availability, minimizing seasonal gaps for processors and exporters.

Cost Efficiency Without Compromising Quality

Economies of scale, established farming practices, and efficient labor structures allow India to remain price-competitive without sacrificing quality. This is why global buyers increasingly shortlist bulk dehydrated onion suppliers from India over other origins.

Processing Excellence: How India Meets Global Quality Standards

Advanced Dehydration Infrastructure

Modern Indian dehydration plants use controlled drying systems that preserve flavor while reducing moisture to optimal levels. Uniform granulation ensures consistent performance across food applications.

Compliance With International Food Safety Norms

Export-oriented processors operate under strict certifications—FSSAI, ISO, HACCP, BRC, Halal, Kosher, and FDA-aligned standards. Traceability, batch consistency, and documentation accuracy are now baseline expectations for food grade dehydrated onion and garlic products.

Low Moisture, High Flavor Retention

Proper dehydration locks in volatile flavor compounds, which is why export quality dehydrated garlic from India often outperforms competitors in taste intensity and shelf stability.

Global Demand Drivers Fueling Market Growth

Processed Food and Ready-to-Eat Expansion

From instant noodles and seasoning sachets to frozen meals and snacks, dehydrated onion and garlic are foundational ingredients in the global processed food boom.

HoReCa and Cloud Kitchen Growth

Restaurants and cloud kitchens need standardized flavor and faster prep. Dehydrated formats deliver both—without the waste or variability of fresh produce.

Clean-Label Ingredient Preference

Consumers are pushing brands away from artificial flavor enhancers. Dehydrated onion and garlic offer natural flavor concentration, aligning perfectly with clean-label trends shaping the dehydrated vegetables market.

Supply Chain Stability Post-Disruption

After years of logistics disruptions, buyers favor ingredients that travel well. Dehydrated formats reduce cold-chain dependency, making global garlic powder demand more resilient.

Why Global Buyers Prefer Indian Dehydrated Onion & Garlic

Reliable Export Ecosystem

India’s port infrastructure, exporter experience, and regulatory familiarity support smooth international trade. Many dehydrated onion exporters India serve long-term B2B contracts across continents.

Flexible Order Volumes

Buyers can scale from trial shipments to container-load quantities without supply disruptions—ideal for growing brands.

Competitive International Pricing

Compared to other origins, India offers a strong balance of price, quality, and volume, giving bulk garlic powder suppliers India a decisive edge.

Customization for Food Manufacturers

Mesh size, moisture content, packaging formats, and labeling can all be tailored—critical for B2B food ingredient sourcing.

Key Application Industries Driving Repeat Demand

Food processing companies rely on dehydrated onion and garlic for formulation stability. Spice and seasoning brands use them as base ingredients. Snack, meat, and convenience food producers value flavor uniformity and shelf-life extension. Even retail private labels increasingly stock ready-to-use dehydrated formats to meet consumer demand.

Sustainability & Ethical Sourcing: An Increasing Buyer Priority

Modern dehydration practices reduce food waste compared to fresh exports. High-density shipping lowers carbon footprint per unit. Many processors work directly with farmers, supporting fair procurement and ethical sourcing—key factors in sustainable food ingredients decisions.

Challenges Buyers Should Be Aware Of (And How India Addresses Them)

Quality variability remains a risk when sourcing from uncertified suppliers. Moisture control is critical during storage and transit. Regulatory documentation—COA, MSDS, phytosanitary certificates—must be accurate and complete. India’s mature export ecosystem addresses these challenges through audits, standardized packaging, and compliance-driven operations.

Future Outlook: India’s Expanding Role in the Global Dehydrated Market

Automation, capacity expansion, and rising demand from emerging markets point to sustained growth. India is no longer viewed merely as a low-cost supplier—it is becoming a long-term partner shaping the future of dehydrated food market and global onion garlic trade trends.

Conclusion: Why Indian Dehydrated Onion & Garlic Are a Strategic Choice

Quality, scalability, compliance, and cost efficiency have made India a preferred sourcing destination for dehydrated onion and garlic worldwide. For buyers seeking reliability—not just price—India delivers consistency at scale.

Within this landscape, exporters like Citadel Global represent a new generation of Indian suppliers focused on clean-label products, traceable sourcing, and export-ready performance. For importers, wholesalers, and food manufacturers looking to build dependable supply chains, partnering with experienced Indian exporters isn’t just a smart move—it’s a strategic one.