- By Admin

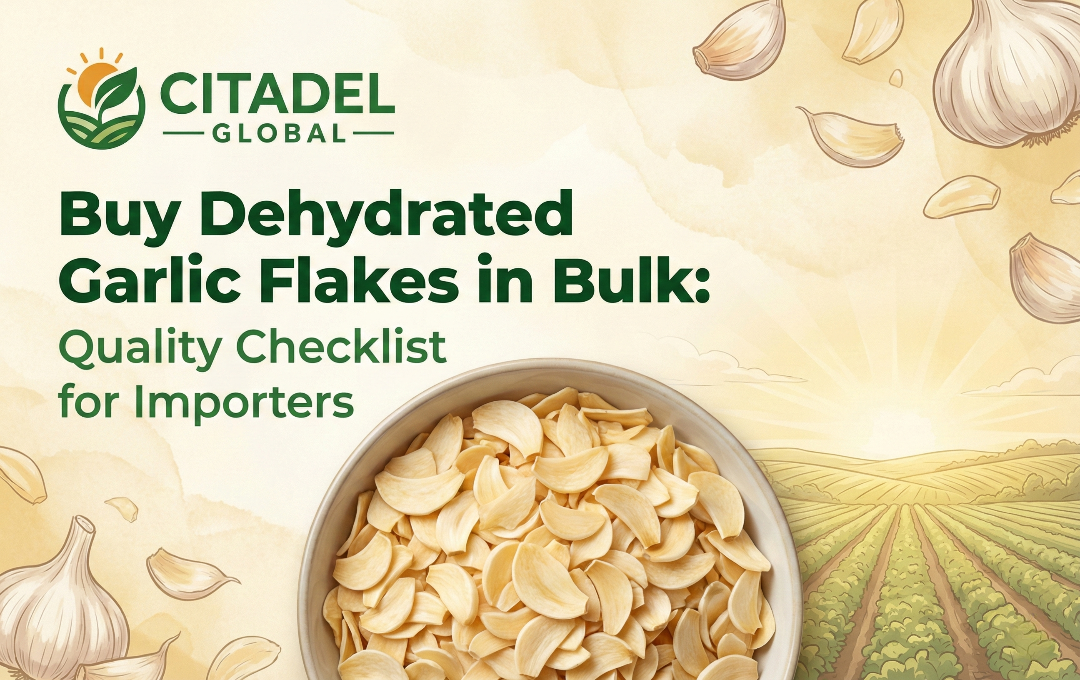

Why Dehydrated Garlic Flakes Are Essential for Global Food Brands

Walk into any industrial kitchen, food processing plant, or large-scale manufacturing unit, and one ingredient quietly shows up everywhere — dehydrated garlic flakes. Not flashy. Not trendy. But absolutely indispensable.

As global food brands scale across borders, they face a non-negotiable challenge: how do you deliver the same flavor, quality, and safety every single time — without slowing production or risking spoilage? Fresh garlic, for all its charm, rarely fits that equation at scale.

That’s where dehydrated garlic flakes step in — offering consistency, shelf stability, and operational ease that modern food production depends on. This article breaks down why global food brands rely on them, how they outperform fresh garlic in industrial use, and what makes them a strategic ingredient rather than just a convenience.

Understanding Dehydrated Garlic Flakes

What Are Dehydrated Garlic Flakes?

Dehydrated garlic flakes are made by peeling fresh garlic cloves, slicing them uniformly, and removing moisture through controlled dehydration. The result? Lightweight, shelf-stable garlic pieces that retain their natural flavor, aroma, and functional properties — without the volatility of fresh produce.

Common dehydration methods include:

-

Air drying, which preserves structure and flavor for industrial use

-

Low-temperature dehydration, designed to minimize nutrient loss

When done correctly, dehydration doesn’t dilute garlic — it concentrates it.

Nutritional and Functional Profile

Despite moisture removal, dehydrated garlic flakes retain many of garlic’s active compounds, including antioxidants and sulfur-based bioactives responsible for its pungency and health value.

Compared to fresh garlic:

-

Flavor is more predictable

-

Shelf life extends from weeks to months

-

No peeling, chopping, or spoilage risk

For manufacturers, that predictability matters more than anything.

Why Dehydrated Garlic Flakes Are Essential for Global Food Brands

Consistent Flavor and Aroma Across Batches

Food brands live and die by consistency. A sauce that tastes different in Tokyo than it does in Toronto damages trust instantly.

Dehydrated garlic flakes deliver uniform intensity and aroma across batches, allowing brands to:

-

Standardize recipes globally

-

Maintain brand identity across markets

-

Avoid seasonal flavor fluctuations found in fresh garlic

That’s why they’re widely used in seasonings, snacks, marinades, and ready-to-eat meals.

Extended Shelf Life and Storage Benefits

Fresh garlic demands climate control, frequent handling, and constant quality checks. Dehydrated garlic flakes, on the other hand, are built for long journeys.

Key advantages:

-

Significantly longer shelf life

-

Lower spoilage and microbial risk

-

Easier warehousing and inventory planning

For global supply chains, fewer losses translate directly into higher margins.

Ease of Use and Process Efficiency

In large-scale production, time equals money. Dehydrated garlic flakes eliminate multiple prep steps:

-

No peeling

-

No cutting

-

No labor-intensive processing

They integrate seamlessly into dry blends, oil infusions, and rehydrated formulations — helping manufacturers move faster without sacrificing flavor.

Cost-Effectiveness for Large-Scale Manufacturing

While fresh garlic may seem cheaper upfront, it carries hidden costs:

-

Waste from spoilage

-

Labor for preparation

-

Higher transport weight

Dehydrated garlic flakes reduce wastage, shipping costs, and operational complexity, making them far more economical at scale — especially for bulk buyers and export-oriented brands.

Versatility Across Global Cuisines

From Asian sauces to Mediterranean rubs and Western snack seasonings, dehydrated garlic flakes adapt effortlessly.

They’re used in:

-

Soups and instant mixes

-

Snack coatings

-

Ethnic ready meals

-

Marinades and spice blends

Their neutral form allows food developers to tailor intensity without overpowering recipes.

Compliance and Safety Standards

Global food brands operate under strict regulatory scrutiny. Dehydrated garlic flakes processed in certified facilities offer:

-

Better microbial control

-

Traceability

-

Compliance with international food safety norms

This consistency makes audits, exports, and large contracts far smoother.

Special Considerations for Food Brands

Choosing the right dehydrated garlic flakes isn’t just about price. Brands must evaluate:

-

Processing standards and certifications

-

Moisture control and particle uniformity

-

Packaging that prevents caking and contamination

-

Supplier reliability and export experience

The wrong supplier can disrupt production. The right one becomes a long-term partner.

Future Trends and Innovations

Demand for clean-label, non-GMO, and minimally processed ingredients is accelerating. Dehydrated garlic flakes fit neatly into this shift.

Emerging trends include:

-

Organic dehydrated garlic flakes

-

Use in functional and wellness-focused foods

-

Increased adoption in plant-based and convenience categories

As food innovation grows, garlic isn’t disappearing — it’s evolving.

Closing Thoughts: Where Quality Meets Global Scale

When food brands scale globally, shortcuts aren’t an option. Dehydrated garlic flakes offer what fresh garlic can’t at industrial scale — consistency, safety, efficiency, and reliability. That’s why they’ve become a backbone ingredient across international food manufacturing.

For brands seeking dependable, export-ready dehydrated garlic flakes, Citadel Global stands out as a trusted partner. As an Indian exporter specializing in clean-label dehydrated agro products, Citadel Global delivers FSSAI-certified, traceable, and export-compliant dehydrated garlic flakes designed for wholesalers, food processors, and institutional buyers worldwide.

With advanced dehydration technology, bulk packaging expertise, and a commitment to purity without preservatives, Citadel Global doesn’t just supply ingredients — it supports consistency at scale.

If your brand values reliability, long shelf life, and uncompromised flavor, sourcing dehydrated garlic flakes from the right partner can make all the difference. And that’s where confidence, quite literally, gets exported.