- By Admin

- Dehydrated Onion Flakes

Things to Check Before Importing Dehydrated Onion Flakes

Introduction

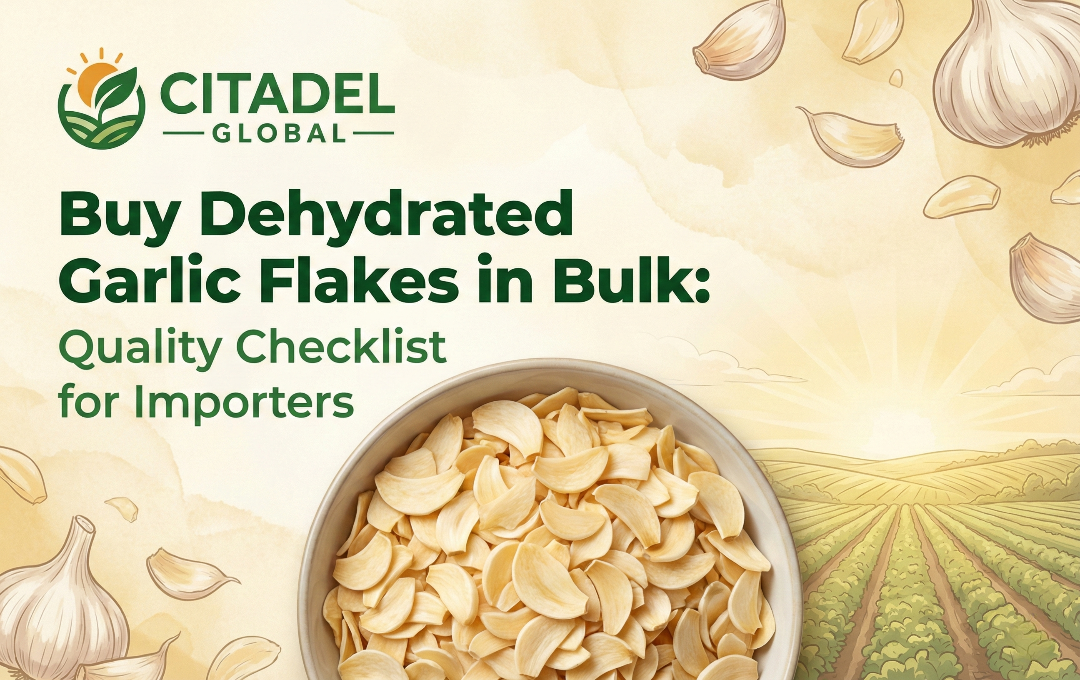

Across global food supply chains, Dehydrated Onion Flakes have quietly become a backbone ingredient. From industrial food processing and seasoning blends to HoReCa kitchens and ready-to-eat meal manufacturers, their long shelf life, consistent flavor, and ease of use make them indispensable. As demand rises, more buyers are turning to imports to secure reliable volumes and competitive pricing.

But importing Dehydrated Onion Flakes isn’t a simple price-driven transaction. Behind every shipment lies a web of food safety standards, regulatory checks, quality benchmarks, logistics planning, and supplier credibility. A single oversight—excess moisture, missing documentation, or poor hygiene controls—can turn a profitable deal into a costly setback.

This article serves as a comprehensive decision-support guide for both first-time importers and experienced buyers. It breaks down what truly matters before signing contracts, issuing purchase orders, or loading containers—so imports remain compliant, consistent, and commercially viable.

Understanding the Global Market for Dehydrated Onion Flakes

The global trade in Dehydrated Onion Flakes is shaped by agricultural cycles, processing capacity, and regional expertise. Major exporting regions include India, China, Egypt, and the United States, each offering distinct advantages in terms of onion varieties, climate suitability, and dehydration infrastructure. On the importing side, demand is strongest in the U.S., European Union, Middle East, and Southeast Asia, driven by large-scale food manufacturing and foodservice consumption.

One of the biggest demand drivers is shelf stability. Unlike fresh onions, Dehydrated Onion Flakes offer extended usability without refrigeration, reducing spoilage and storage costs. This makes them ideal for global trade and long-distance supply chains.

However, pricing in this market is far from static. Onion crop yields fluctuate seasonally, weather disruptions affect raw material availability, and dehydration output varies based on processing efficiency. As a result, buyers often face price volatility that cannot be managed through short-term sourcing alone.

This is why sourcing from regions with strong processing infrastructure matters. Exporters operating in well-established agro-processing ecosystems are better positioned to deliver consistent quality, predictable supply, and compliance-ready shipments—even during volatile crop cycles.

Supplier Evaluation and Due Diligence

Assessing Supplier Reputation and Export Experience

The foundation of a successful import begins with supplier credibility. An exporter’s track record matters far more than a low quote. Buyers should evaluate how long the supplier has been operating, which countries they export to, and whether they understand the regulatory requirements of the destination market.

Suppliers without export experience often struggle with documentation accuracy, labeling compliance, and shipment coordination. These gaps can result in customs delays, rejected consignments, or inconsistent product quality across batches—risks that compound with every order.

Verifying Food Safety and Quality Certifications

Certifications are not paperwork formalities; they are risk controls. For Dehydrated Onion Flakes, internationally recognized certifications signal that food safety systems are embedded into processing, not added as an afterthought.

Key certifications include FSSC 22000 or ISO 22000 for food safety management systems, HACCP for hazard identification and control, and BRCGS compliance for buyers supplying EU and UK retail chains. For U.S. imports, FDA registration is non-negotiable. Depending on market needs, Halal, Kosher, or Organic certifications may also be essential.

Missing or invalid certifications can lead to customs rejection, product recalls, or buyer liability—costs that far exceed any upfront savings.

Facility Audits and Hygiene Standards

A supplier’s facility reveals more than a brochure ever will. Clean drying chambers, controlled sorting areas, hygienic packing lines, and proper pest control systems are essential for safe Dehydrated Onion Flakes production.

Third-party audits add another layer of assurance, especially for buyers unable to conduct on-site inspections. In recent years, video audits and digital walkthroughs have become practical tools for verifying sanitation, metal detection systems, and operational discipline before shipments are dispatched.

Batch Traceability and Supply Chain Transparency

Traceability is no longer optional. Buyers must be able to trace Dehydrated Onion Flakes back to their source in case of audits, recalls, or compliance checks. This requires batch coding, lot numbering, and documented raw material sourcing.

Exporters who maintain transparent supply chains offer greater accountability—and protect buyers from reputational and regulatory risk.

Product Quality and Technical Specifications

Physical Characteristics of High-Quality Dehydrated Onion Flakes

Quality assessment begins with the senses. High-grade Dehydrated Onion Flakes should exhibit a pale golden to off-white color, free from browning or dark patches. Texture should be free-flowing, not clumped or sticky, and the aroma should be clean and mildly sweet—never musty or burnt.

Poor dehydration techniques often result in uneven color and compromised flavor, which directly affect end-product performance.

Moisture Content and Shelf-Life Stability

Moisture control is one of the most critical technical parameters. Industry standards typically require moisture levels at or below 6%. Excess moisture increases the risk of microbial growth, clumping, and spoilage during storage or transit.

Properly dehydrated Dehydrated Onion Flakes, stored under recommended conditions, can achieve shelf lives ranging from 12 to 24 months—making them suitable for long-haul logistics.

Microbiological and Chemical Safety Standards

Food safety extends beyond appearance. Buyers must ensure that Dehydrated Onion Flakes meet microbiological limits for pathogens such as Salmonella, E. coli, yeast, and mold. Third-party laboratory testing and a valid Certificate of Analysis (COA) are essential components of quality assurance.

Chemical safety is equally important. Compliance with FDA, EFSA, or other destination-country standards protects both the importer and the end consumer.

Ingredients, Additives, and Processing Integrity

At its core, Dehydrated Onion Flakes should contain one ingredient: onion. The presence of unauthorized preservatives, artificial colors, or excessive sulphur content raises serious compliance concerns.

Clean-label processing not only meets regulatory expectations but also aligns with growing consumer demand for transparency.

Onion Variety, Cut Size, and Application Suitability

Different applications require different specifications. Buyers must confirm the onion variety used—white, red, or pink—as well as flake size and mesh specifications. Soup manufacturers, snack producers, and spice blenders all require distinct particle profiles.

Clear specification alignment prevents downstream formulation issues and costly rejections.

Packaging, Labeling, and Shelf Protection

Export-Grade Packaging Requirements

Packaging plays a decisive role in preserving quality. Dehydrated Onion Flakes should be packed in food-grade, moisture-resistant inner liners, often double-layered poly bags, supported by sturdy outer cartons.

This structure protects against humidity, contamination, and physical damage during transit.

Labeling Compliance for Import Markets

Accurate labeling is a legal requirement. Mandatory elements include product name, net weight, country of origin, batch or lot number, and manufacturing and expiry dates. Non-compliant labels can halt shipments at ports, triggering delays and penalties.

Import Documentation and Customs Readiness

Mandatory Import and Shipping Documents

Documentation errors remain one of the leading causes of shipment delays. Importers must ensure complete and accurate paperwork, including Import Export Code (IEC), Phytosanitary Certificate, Certificate of Origin, Commercial Invoice, Packing List, Bill of Lading or Airway Bill, Certificate of Analysis, and insurance coverage.

Each document plays a role in customs clearance and risk assessment.

HS Code Classification and Customs Accuracy

Correct HS code classification for Dehydrated Onion Flakes determines duty rates and compliance obligations. Misclassification can trigger inspections, fines, or shipment holds. Working closely with customs brokers helps mitigate this risk.

Logistics, Storage, and Transit Risk Management

Choosing between sea and air freight depends on urgency and cost considerations. Regardless of mode, shipments must be protected from moisture exposure. Dry, ventilated containers and careful transit planning reduce spoilage risk.

Upon arrival, proper storage—cool, dry, and well-ventilated—is essential to preserve quality.

Financial and Commercial Considerations

Pricing Structure and Cost Drivers

Pricing for Dehydrated Onion Flakes is influenced by onion variety, grade, dehydration method, seasonal availability, order volume, and packaging requirements. Understanding these drivers helps buyers evaluate quotes realistically.

Incoterms and Risk Allocation

Incoterms such as FOB, CIF, and CNF define cost responsibilities and risk transfer points. Clear agreement on terms prevents disputes and clarifies insurance obligations.

Payment Terms and Trade Security

Secure payment structures—whether advance payment or letters of credit—protect both parties. First-time transactions benefit from conservative trade finance arrangements to minimize exposure.

Regulatory and Legal Compliance in the Destination Country

Importers must comply with destination-country food laws, registration requirements, and inspection protocols. Non-compliance can lead to fines, product destruction, or import bans. Consulting customs agents and food compliance experts is a prudent investment.

Common Import Risks and How to Avoid Them

Quality mismatches, moisture damage, documentation errors, and supplier non-compliance are recurring risks in Dehydrated Onion Flakes imports. The most expensive mistakes often stem from inadequate due diligence.

A holistic evaluation approach—covering supplier credibility, technical specifications, logistics, and compliance—saves money over time and protects brand reputation.

FAQs: Problem-Solving for Importers

How do I verify the quality of Dehydrated Onion Flakes before shipment?

Pre-shipment samples, Certificates of Analysis, and third-party inspections provide early assurance.

What moisture level is acceptable for long shelf life?

Industry standards generally require moisture content at or below 6% to prevent spoilage.

Can Dehydrated Onion Flakes be rejected at customs?

Yes. Labeling errors, microbiological non-compliance, or missing documents can lead to rejection.

Which certifications are mandatory for U.S. or EU imports?

FDA registration is essential for the U.S., while BRCGS and recognized food safety systems are critical for EU markets.

How long can Dehydrated Onion Flakes be stored safely?

Under proper storage conditions, shelf life typically ranges from 12 to 24 months.

What is the biggest mistake first-time importers make?

Over-prioritizing price while underestimating compliance and quality consistency.

Conclusion

Importing Dehydrated Onion Flakes successfully requires more than transactional sourcing. Supplier credibility, product quality, documentation accuracy, and financial clarity all play decisive roles. Long-term success is built on consistency, transparency, and compliance—not shortcuts.

For importers seeking a reliable partner that aligns with these principles, Citadel Global stands out. As a specialized Indian exporter of clean-label agro products, Citadel Global combines FSSAI-certified processing, advanced dehydration technology, full traceability, and export-ready documentation to deliver confidence with every shipment. For buyers who value purity, compliance, and dependable supply, working with a partner that treats quality as a commitment—not a claim—makes all the difference.

Choosing the right supplier today protects your business tomorrow.