- By Admin

- Dehydrated Onion Pieces Exporter from India Best Dehydrated Onion Supplier India Dehydrated Onion Manufacturer India, Onion Pieces Exporters in India

Best Dehydrated Onion Pieces Exporter from India

The Untold Truth Behind the Best Dehydrated Onion Pieces Exporter from India

Let’s be brutally honest—dealing in dehydrated onion is not a glamorous job.

But it’s a damn critical one.

Because when your dried onions don’t rehydrate right, you’re not just dealing with product loss. You’re dealing with reputation decay.

No fancy branding can save you from a bad batch.

And yet, buyers across continents keep falling into the same trap: going for volume instead of value.

You’ve probably faced it too.

You order from what looks like a reputed Dehydrated Onion Pieces Exporter from India. You think the specs are tight. Then the shipment arrives, and suddenly—

-

The flakes are pale,

-

The pieces smell stale,

-

Rehydration is patchy, and

-

Flavor? Practically missing in action.

If you’ve been there, you already know this isn’t about onions.

This is about accountability.

And if you’re sourcing for mass food manufacturing or institutional kitchens, you can’t afford to get this wrong.

When Onions Lose Their Identity, You Lose Market Integrity

There’s a global myth that India, being the world’s second-largest onion producer, automatically guarantees quality.

False.

India produces over 2 million MT of onions annually, but only a tiny fraction (~4%) undergoes export-grade dehydration. Why? Because most dehydration units are focused on quantity, not qualitative food science.

Now consider this:

-

In rehydration labs across the EU, 30% of Indian-origin dried onion samples fail to meet the 85% rehydration ratio required for ready-meal manufacturers.

-

18% of consignment rejections are linked not to pathogens—but to inconsistent cut sizes, irregular moisture levels, and volatile sulfur loss that compromises flavor integrity.

-

Worse yet, a high sulphur loss (above 35%) means your onion may pass lab tests… but completely fail in taste performance on the plate.

And when that happens, your clients don’t come back.

Or worse—they do. With complaints.

This is exactly why working with a proven Dehydrated Onion Manufacturer India is no longer a back-office procurement call. It’s a strategic quality decision.

The Anatomy of Quality: What Makes or Breaks a Dehydrated Onion Piece

It’s easy to throw around terms like “premium quality.” But here’s what it really takes to build an onion product that survives shelf time and satisfies flavor expectations post-rehydration:

1. Moisture Control (Target: 4%-5%)

Any higher than that, and you invite microbial bloom.

Any lower, and you compromise on pliability.

2. Pungency Lock (Allyl Propyl Disulfide Retention)

This compound is the very soul of onion flavor.

Loss of over 30% renders the onion useless in sauces, soups, and dry rubs.

3. Granular Uniformity (±1 mm tolerance)

Matters most for machines. Because automated blending lines don’t care about your excuses—they clog if granules are irregular.

4. Ash Content (Below 4%)

The lower the ash, the cleaner the drying. High ash = poorly handled batches.

5. Sensory Retention (Smell, Color, Bite)

You can’t test this with a lab kit. You test this when a chef opens the bag and doesn’t flinch.

And here's a little-known truth: only a handful of Onion Pieces Exporters in India operate at a level where these parameters are standard, not exceptions.

Who Really Needs This Level of Consistency?

You do—if your business stands on food quality.

Our clients aren’t mass-market quick sellers. They’re:

-

Global seasoning brands whose entire SKU depends on predictable, repeatable taste.

-

Private-label exporters to Europe and Japan, where compliance documentation is stricter than airport security.

-

Meal kit companies who need products that hold up through freeze-drying, vacuum-packing, and long-haul shipping.

-

Snack manufacturers with ultra-sensitive flavor matrices where one wrong onion batch ruins an entire product line.

We get it. You’re not sourcing “onion.”

You’re sourcing repeat performance.

The kind that builds buyer confidence batch after batch.

Real Talk: No One’s Tolerating Mediocrity Anymore

Exporters used to get away with it.

“Indian origin, 99% purity, 2% moisture loss”—those labels used to pass.

Not anymore.

Today, food importers run:

-

Sulfur profile breakdowns,

-

Pesticide residue screenings,

-

Batch-wise traceability logs,

-

Even UV fade tests to check for artificial whitening!

And here’s the thing: if your supplier can’t provide batch integrity lab-backed consistency, you’re gambling every single time.

Even if the paperwork looks perfect.

This is why aligning with an Indian Dehydrated Onion Exporter who treats food safety, not just container counts, as a KPI is everything.

Case Study: How A Canadian Dry Soup Brand Cut 70% Risk

A health-forward Canadian brand—let’s call them Brand Z—suffered repeated product recalls because their onion ingredient was underperforming.

Batch inconsistencies were creating gritty textures, and pungency faded within 60 days.

They switched to a small-batch Dehydrated Onion Manufacturer in India using solar pre-processing and low-heat dehydration, followed by vacuum-pack sealing.

Within two quarters:

-

Complaints dropped by 93%.

-

Shelf-life extended by 7 months.

-

Their largest retailer renewed a 3-year contract.

That wasn’t luck. That was ingredient alignment with processing ethics.

Here’s What You Really Deserve in a Supplier

Let’s stop talking products. Let’s talk partnership realities.

A reliable Dehydrated Onion Supplier India should be delivering:

-

Consistent sensory profile across 3 quarters

-

Third-party lab testing access per batch

-

Adaptive packaging options: LDPE, PP, Kraft paper or layered foil

-

Moisture-barrier shipping protocol for long-haul routes

-

Custom cut-size calibration based on your equipment specs

-

Real traceability — not just a farm name but actual harvest cycle data

Because your buyer doesn’t care how your onion looks in a lab.

They care how it performs on a plate.

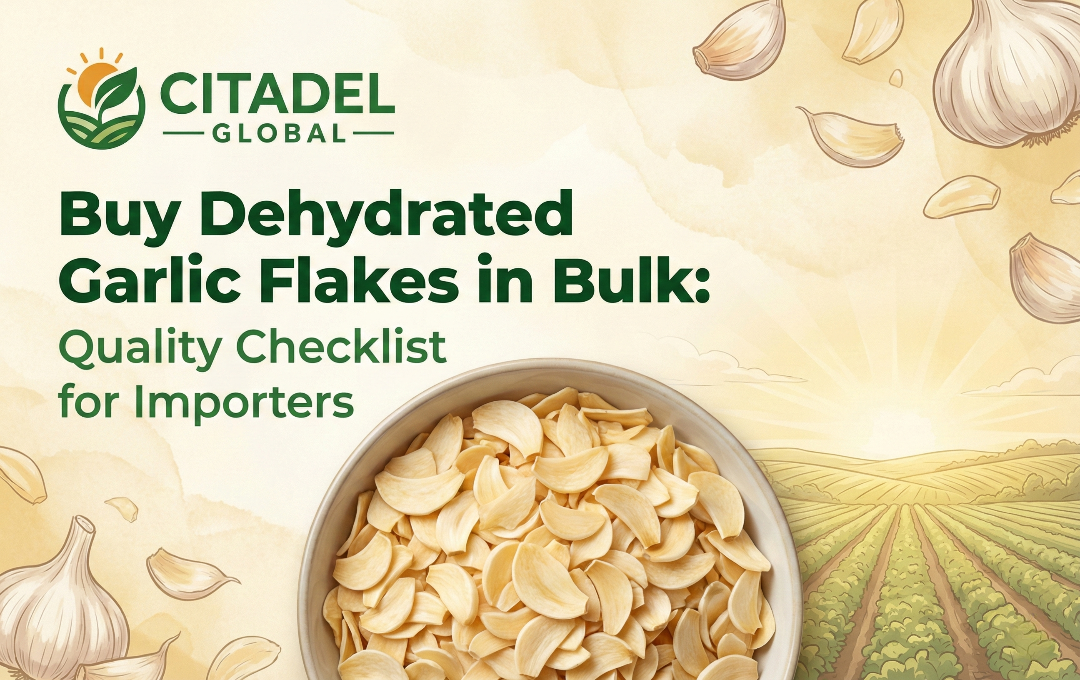

Citadel Global — Because You Deserve Confidence in Every Cut

Now here’s the quiet truth.

You won’t see our name blasted on trade fair banners.

We don’t stuff inboxes with flamboyant pricing decks.

And we didn’t start in a shiny warehouse with air-conditioned reception lobbies.

We started with a small team and a single belief:

If the world tastes purity, it will come back.

Today, Citadel Global is the trusted name among serious importers looking for a Dehydrated Onion Pieces Exporter from India that doesn’t fake the fundamentals.

From uniform onion cuts to clean-label bulk exports, from FSSAI-certified drying units to customized packaging by country, we serve one purpose:

To be the Indian Dehydrated Onion Exporter your competitors wish they had found first.

So, if you're looking for a Best Dehydrated Onion Supplier India not just in name—but in every damn shipment—

Let’s talk. Quietly. Confidently. Consistently.